Industry Trends

Brad Leavitt Talks Desert Home Design with LP® Structural Solutions Products

Brad Leavitt, founder and president of Arizona-based construction company A Finer Touch (AFT) Construction, has been building homes in Arizona for over a decade. A recent project for the CEO of Build Magazine, Ted Bainbridge, led him to a secluded Arizona property with scenic views, aptly named “Desert Island.”

We talked with Leavitt about the nuances of building this modern desert home and how LP Structural Solutions products helped along the way.

Exterior Sheathing Options for a Cooler Interior

Like most Arizona landscapes, this location was no escape from the hot desert sun. But as an industry pro, Leavitt has learned to work with the elements by opting for smarter exterior sheathing options for the roof, like LP® TechShield® Radiant Barrier.

"LP TechShield Radiant Barrier has been a product we have continued to use on all our builds for this reason. It protects the home from the intense effects of the Arizona sun, and it can reduce the attic temperature up to 30 degrees-a huge benefit for us and the homeowner," says Leavitt.

LP TechShield panels are constructed with a thin, radiant barrier sheet laminated to LP® OSB sheathing. The reflective surface redirects radiant heat created by the sun, building energy efficiency directly into the home, which was a top priority for the homeowner on this build.

Get a Tight Building Envelope with Seam & Flashing Sealant

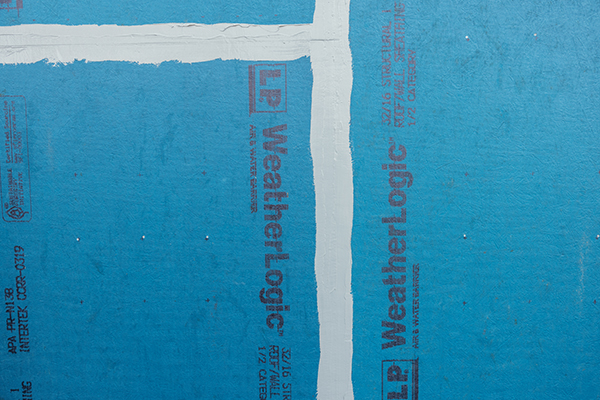

In addition to LP TechShield Radiant Barrier sheathing, Leavitt opted to use LP WeatherLogic® panels and LP WeatherLogic® Seam & Flashing Sealant for a tight building envelope.

“We don’t have any fear of water intrusion with this sealant,” says Leavitt, who chose sealant over tape for its ease of use.

With a full cure in as little as just 24 hours, LP WeatherLogic Seam & Flashing Sealant allows you to save time on the jobsite.

The Benefits of a Single Manufacturer

Whether you’re taking on a basic home design or something more complex, Leavitt’s key to a smooth construction process is using a single manufacturer.

"It makes it super easy for us as builders," says Leavitt. "Fewer chains of communication, fewer breakdowns, more convenience and more efficiency."

For Leavitt, the needs of the homeowner, the climate, and the structure all inform his product choices. Having the portfolio of LP Structural Solutions as a go-to for core products simplifies the process while still allowing him to choose products that suit the unique needs of his builds.

Interested in learning more about the LP Structural Solutions portfolio? Explore our resilient solutions here.

Continue Reading

Resiliency Solutions

5 minIntroducing LP® SmartSide® ExpertFinish® Naturals Collection™: Nature-Inspired Beauty Meets Engineered Performance

We’re excited to introduce the LP® SmartSide® ExpertFinish® Naturals Collection™, a bold new addition to our trusted line of engineered wood siding and trim that delivers the warmth and beauty of nature with the advanced protection and performance builders and homeowners expect.

Labor Solutions

5 minChoosing the Right LP® Structural Solutions Product for Your Build

When it comes to building strong, reliable, and high-performing structures, the materials you choose matter. At LP Building Solutions, we understand that every project, whether it's a single-family home or a multifamily development, requires structural components that meet your needs for strength, durability, and efficiency.

Sustainability Solutions

5 minBuilding a More Sustainable Future with LP Building Solutions

In today's world, sustainability is no longer just a buzzword, it's a blueprint for responsible living and smarter building. As the construction industry seeks ways to reduce its environmental footprint, LP Building Solutions is focused on providing innovative building materials for eco-conscious builders to help reshape what it means to build sustainably

News & Stories3 min

History of Partnership with Gary Sinise Foundation

The LP Foundation is a proud partner of the Gary Sinise Foundation, which supports wounded veterans in several ways. You can learn more about the LP Foundation here.